Purpose of PCB Surface Finish

*Provides a solderable surface for Component assembly.

*Protect Copper Surface from Oxidation.

*Provide a surface appropriate for wear related parts.

High Performance Surface Finish

*Mixed Technology Board Designs

*Solderable,SMT and Thru-hole

*Wire Bondable

*Contact Resistance

*Co-Planar Surfaces

*Compatability with variety of fluxes & paste

*Cost effective

*Environment

Available Surface Finishes

*Electroless Nickle-Immersion Gold

*Immersion Silver

*Hot Air Solder Level

*Organic Solderability Preservative

*Electrolyte Nickel – Hard Gold

*Electrolyte Nickel – Soft Gold

Surface Finish Details

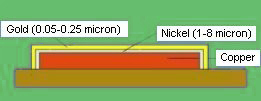

*Electroless Nickel-Immersion Gold (ENIG)

A two layer, gold over nickel, metallic surface finish

plated onto the copper base by means of a

chemical decomposition process.

Advantage: Disadvantage:

| *Typical Thickness: 3-8 uin gold over 150-250 | *Narrow process window |

| uin nickel | *Higher cost than HASL(1.5 to 2.0 times) |

| *Excellent Corrosion resistance | *Back pads: brittle solder joints |

| *Good for aluminium wire bonding | *Fatigue failures on large BGA packages |

| *Excellent flatness for fine-pitch technology | *Skip plate |

| *Excellent Solderability | *Extraneous nickel plating |

| *Excellent shelf life(12 mo) | *Solder mask capability with the nickel bath |

| *Good surface contrast | |

| *Good contact resistance | |

| *High Aspect Ratio Capability |